Let’s say you’re a truck driver driving down the interstate going 65 miles per hour. You notice a traffic jam a few football fields away and you slowly begin to press down on the brakes. As you approach the traffic jam, you come to a complete halt. When you come to a stop, you hear a slight squeaking sound with a hiss coming from behind the tires. This 80,000-pound vehicle has slowed completely down to your foot’s steady command.

How do air brake work in trucks? Air brakes work when the driver steps on the brake pedal pushing the air from the reservoir tanks into the brake chamber, forcing down a piston. The slack adjuster is then moved by the piston which is attached to the push rod.

The slack adjuster then connects the push rod to another rod causing that rod to rotate. It’s the S-cam that pushes the brake shoes toward and against the lining of the drum brake which in turn slows down the vehicle. The return spring eases the drum brake back into its original position.

This may seem to be a lot of information of the Air braking system, but truthfully, it’s not even close. The further you scroll down this page the more detail you’ll find about the intriguing brake system.

Knowledge about the Braking System

The air brake system, which was first used in 1872 on the railway system, is now the three-valved system that is now used most commonly in trucks, semi-trailers, and buses.

It is a way of using air to transfer pressure from the pedal of the large vehicle to the service brake line. That hissing and squeaking going on behind the tires are the bypass valves automatically at work to make sure the air pressure remains at the correct level.

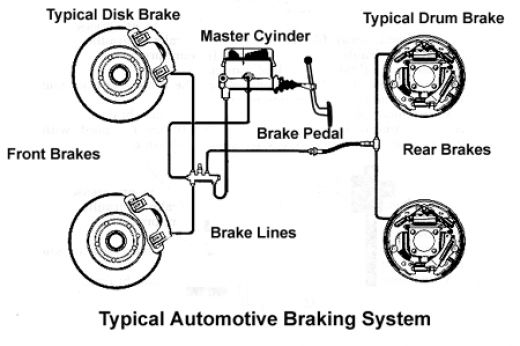

Most small cars have hydraulic brake systems so you won’t find air brake systems in something like a 4-door Sedan. Trucks, however, use the air brake system due to reliability. Since air is an unlimited source, there is never a shortage of it and, there is no need for a refill. The only maintenance is manually opening the drain valve and refilling the alcohol evaporators. The air as a braking mechanism also allows for the coupling of trucks.

Beneath the truck’s exterior, there is a lot of components that assures the vehicle will slow down when the brake pedal is depressed.

The Components of the Air Braking System

- Air compressor pumps air into the air storage tanks.

- Air Compressor Governor is in control of the level at which the air compressor holds air in the storage tanks.

- Air reservoir tanks hold the pressurized air that is used in the braking system.

- Drain valves are in use when the vehicle is not running. They release “drain” the air.

- Foot valve also known as the brake pedal is the trigger that releases air from the reservoir tanks.

- Brake chambers are containers that hold the slack adjuster which moves the diaphragm or cam mechanism.

- A push rod is a steel rod that connects the slack adjuster to the brake chamber. When it is depressed, the brakes are let go. If it is extended, the brakes are applied.

- Slack adjusters connect the push rod to the S-cam brake in order to adjust the distance between the brake shoes.

- Brake S-cam is an S-shaped cam the separates the brake shoes from the brake drums.

- The brake shoe is a steel mechanism that uses the lining to create friction against the brake drum.

- The Return Spring is a strong spring that returns the brake shoes to an open position when they are not in use.

The three-valved Air brake system is the new design of the air brake system that has defined a new way of slowing down trucks and trailers.

Principles in the Air Braking System:

- Charging: First, the system must be filled with air before the brakes can be released.

- Applying: Once the system is filled with air, the air pressure decreases when the brakes are pressed. When the air decreases, a valve lets air back into the storage tanks.

- Releasing: When applying the brakes, air will be released. All that pressure will ease up the brake allowing for the three-valve system to fill up the supply tank.

Air Brakes on a Semi-Tractor are Connected by Two Lines

The first being the emergency line. Also known as the supply line, It is a red line or fitted red line, that lies above the dashboard. This line applies the air pressure that fills the semi-trailer storage tanks and ignites the piston that activates the brakes.

The smaller, blue line is the service line. Pressing down the brake pressurizes the blue service line. This interaction initiates a valve in the trailer to guide air pressure from the storage tanks and the supply line towards the brake cylinders where it shifts the piston that initiates the brakes.

When the pedal is released, the pressure on the service line is decreased. When the service line pressure drops, the valve in the trailer blocks the air supply in the storage tanks, while decreasing the force in the brake cylinder and releasing the brakes.

Differences Between the Braking Systems

For about 135 years the air brake system has proven that it is the top notch brake method for Large on-highway trucks. But as automotive technology progresses, new ways of slowing down the vehicle were added to the mix. From traction control to ABS ( anti-lock) to hydraulics, trucks has become equipped with a more stopping power than ever before. But it took a large quantity of accidents for engineers to introduce another braking system into the trucking industry.

But still, each system has its flaws.

Disadvantages of the Air Brake system:

- Since air is compressible, a large amount of air must reach the brake chamber from the reservoir tank to slow down the vehicle. This causes a much longer stopping distance and more awareness from the driver.

- When air expands, it cools. When air cools, it condenses. When it is cold, the condensed air may freeze and shut down the braking system.

Advantages the Air Brake system:

- The reliability of the air brakes. The three-valved system is in operating conditions at the start. Only when the air is compressed are they released.

- The braking fluid used in braking systems like hydraulics are much more expensive than air. Which is freely available I hope.

- Since air is everywhere, the chances of brake failure are massively less than any other braking system.

Advantages of hydraulic brake system with ABS:

- The stopping power of this system is much more than the Air Brake system based on the physical structure alone.

- Leaking of fluid is the main cause of brake failure in hydraulic systems. Leak-free couplers can prevent leaking.

- Trucks that used hydraulics in other areas already have the pumps installed. Which in turn, will save a lot of money if and when the braking system is added to the vehicle.

Conclusion

The advantages of Air brake system outweigh the advantages of the hydraulic system in many ways. But when integrated, this combination can save many lives. The Air Brake systems remain as the go to system for the trucking industry today. It only takes a split second of hesitation for someone to lose their lives on the road.

The Air brake system may have a much longer stopping period than that of hydraulics, but it is the reliability and driver awareness that has kept it going on for so long.

Technology will not slow down and one day another effective brake system will be stormed up. That too will be flawed in some way, but the chances of lives being saved after that split second of hesitation may greatly increase.